| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: 200ZP-53

Working Pressure: Low Pressure Pump

Influent Type of Impeller: Single Suction Pump

Position of Pump Shaft: Horizontal Pump

Pump Casing Combined: Horizontal Split Pumps, Radial Split Casing

Mounting Height: Suction Centrifugal

Impeller: Closed

Usage: Pump

Materials: Anti-Wearing Cast Iron, CD4MCU, Cr26, Cr30, Zg40mn2

Shaft Sealing: Mechanical Seal And Packing

Additional Info

Packaging: Wooden case or Frame steel Case

Productivity: 1100000 sets/year

Brand: GAOFENG

Transportation: Ocean,Land,Air

Place of Origin: Zigong,Sichuan,China

Supply Ability: 110000 sets/month

Certificate: ISO9001

HS Code: 8413709990

Port: Shanghai,Guangxi,Chengdu

Product Description

Heavy Duty Slurry Pump/Centrifugal Slurry Pump/Anti-Wearing dregs liquid Pump

Brief introduction:

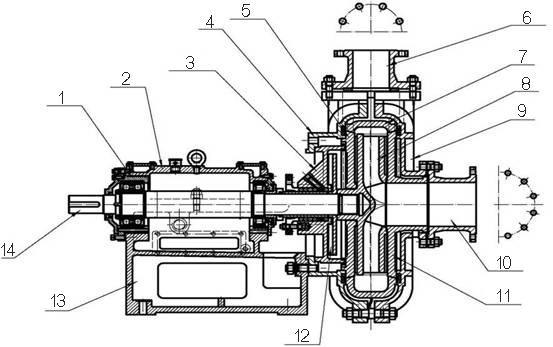

1. Bearing box 2. Bracket cover 3. Vice impeller chamber 4. Pump casing 5. Back guard board 6. Outlet pipe

7. Jacket 8. Impeller 9. Pump cover 10. Inlet pipe 11. Front guard board 12. Vice impeller 13. Bracket 14. Shaft

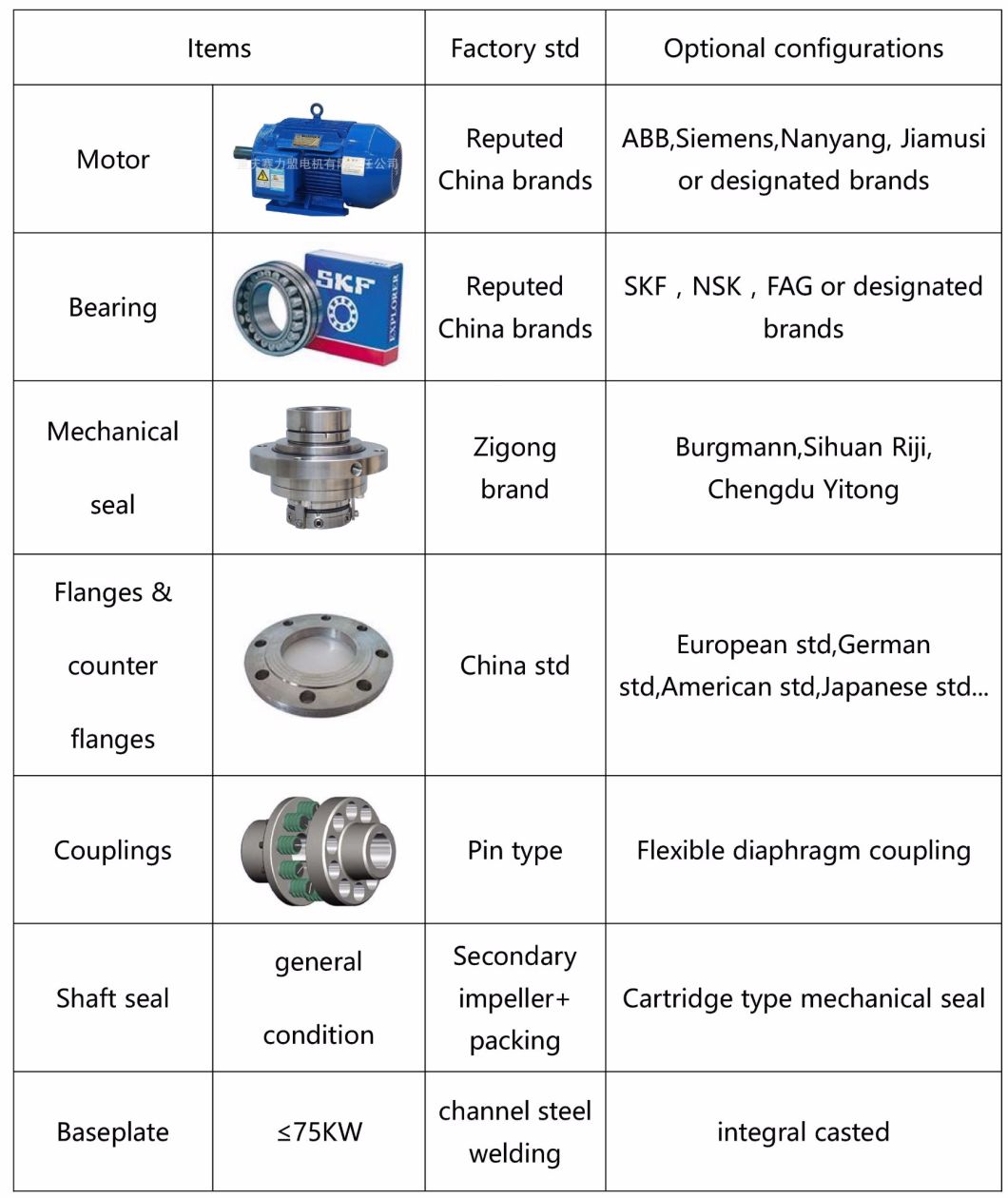

Configuration: