| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: ZHH400

Impeller Number: Single-Stage Pump

Working Pressure: Low Pressure Pump

Influent Type of Impeller: Single Suction Pump

Position of Pump Shaft: Horizontal Pump

Pump Casing Combined: Horizontal Split Pumps

Mounting Height: Suction Centrifugal

Impeller: Closed

Usage: Pump

Materials: SS304, SS316, SS316L, Titanium, Monel, 2205, CD4MCU

Motor Brand: ABB, Siemens Or Reputed Chinese Brands

Flange Standard: Customized

Additional Info

Packaging: Wooden case or Frame steel Case

Productivity: 1100000 sets/year

Brand: GAOFENG

Transportation: Ocean,Land,Air

Place of Origin: Zigong,Sichuan,China

Supply Ability: 110000 sets/month

Certificate: ISO9001

HS Code: 8413709990

Port: Shanghai,Guangxi,Chengdu

Product Description

ZHH horizontal Mixed flow chemical pump

This type of pump is also called Centrifugal mixed flow pump, Chemical process pump or Ss centrifuigal industrial pump.

1. Product parameters:

Flow rate: 200~8300 (m3/h)

Head: 5~19 (m)

Speed: 490-1450rpm

Temperature: 0~105°C

2. Product characteristics

The pump is a horizontal, single-stage, single-suction, cantilever, volute mixed-flow pump, direct-coupled transmission, pump and motor on the common chassis welded by the steel, and the direction of the pump impeller is clockwise from the motor transmission side.

3. Product structure

Pump head

The pump body, impeller, impeller, rear pump cover, inlet chamber, packing chamber and other over-current parts are made of 1Gr18Ni12Mo2Ti stainless steel, which has strong adaptability to various medium corrosion. The pump body supports the bottom surface and the pump body center inlet. Central exit. The rotor part can be removed back together with the rear pump cover when inspecting replacement parts, and the inlet and outlet lines do not have to be removed.

Shaft seal

The shaft sealing device is composed of a dynamic seal and a packing seal. The impeller drive side has a back blade and a counter impeller, which can make the hydraulic pressure drop of the shaft seal part when the pump is running, ensuring no leakage of the slurry, and sealing by packing when running. The water-sealed tube is filled with clean water larger than the system pressure, and the filler is recommended to use TFA carbon fiber asbestos packing.

Bearing department

The bearing frame is made of ductile iron. The front bearing is a single row short cylindrical roller bearing. The rear bearing is a back-to-back configuration of the radial thrust ball bearing. The axial position of the impeller in the pump bearing can be adjusted by adjusting the rear bearing housing. The position inside the bearing frame hole is controlled. The bearing frame is connected to the pump body through the rear pump cover, and has a support plate and a chassis at the rear thereof. The bearing is made of N46 oil, and the oil level is displayed from the oil mark.

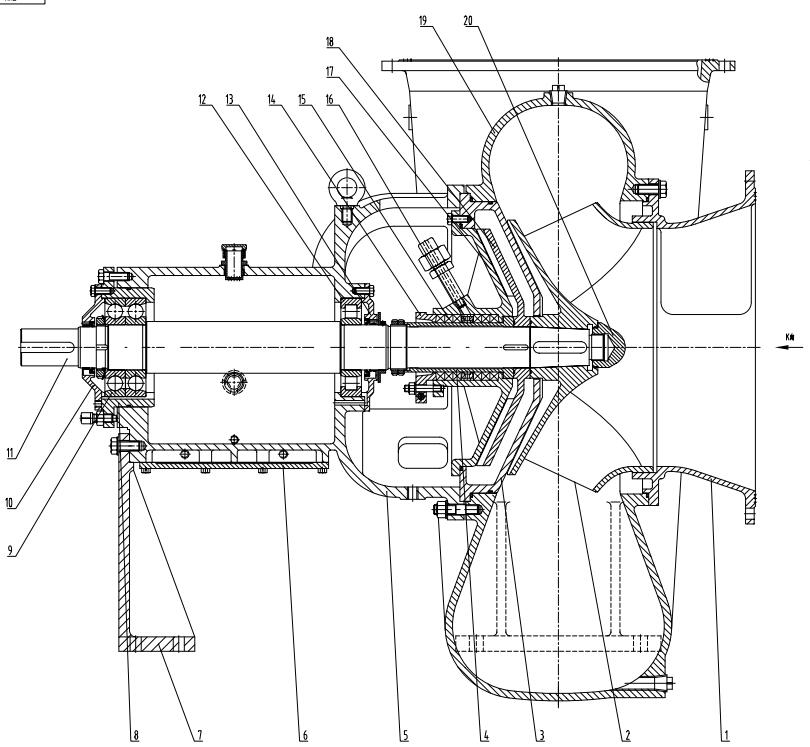

4.Structure

1.front cover 2. impeller 3.back cover 4.shaft sleeve 5.bracket 6.water seal plate 7.bering support

8.bearing box 9.back bearing 10.back bearing gland 11.shaft 12.front bearing 13.front bearing gland

14.packing gland 15.packing 16.packing seal 17.packing room 18.sub-impeller 19.casing 20.impeller nut

4. Product materials

Main parts and materials: gray cast iron, aluminum cast iron, cast steel, all kinds of stainless steel, etc.

5. Product configuration

Motor: Domestic Motor: Chongqing, Xi'an, Nanyang, Jiamusi, Shanghai, Shandong

Imported brands: ABB, Siemens, AB

Bearing: domestic Harbin, Wafangdian, Luoyang,

Import: SKF, NSK, FAG

Reducer: Domestic Jiangsu Tailong, Great Wall, Jiangsu International Trade

Imported brands: SEW, Flanders

6. Use conditions

The pump is specially designed and manufactured according to the slurry circulation requirements of ammonium phosphate and potassium fertilizer systems. Therefore, it is ideal as a slurry circulating pump for ammonium phosphate and potassium fertilizer systems. It can also be used in other chemical plant systems like industrial and mining to make corrosive suspension. The medium implements a large flow forced circulation.

7.packing and shippment